The Assembly and Testing of New Energy Electric-motor

The assembly and testing line of new energy electric-motor is a complete set of flexible assembly and testing system with accessories, which generally consists of rotor assembly line, stator and rotor marriage line, testing line, trial production line, MES, etc.

Rotor assembly line

As a whole, rotor assembly line is a kind of linear layout( 2 layer conveyor drove via chain) that assembles and tests rotors and places rotors on stator and rotor assembly line through rotor assembly station, tightening, dynamic balance testing, magnetization & magnetic inspection, pressing of bearing& end cover, gantry transferring system.

Stator and rotor marriage assembly line

The assembly and transfer of electric-motor can be reached by several processes which contain shrinking, pressing and testing of stator and housing, cooling, tunnel, leak test, automatic spreading , pressing the end cover, turnover station, rotor and stator marriage, assembly and testing of resolver, comprehensive testing, installation of accessories, robot transfer station.

Testing line

After robot transfer, no load testing, load testing, leak test, pneumatic and laser marking process, a qualified motor will be unload to the OK part tray.

Trial production line

Motors are transported to each station or repairing area to fulfill assembly or repairing by KBK and trolley.

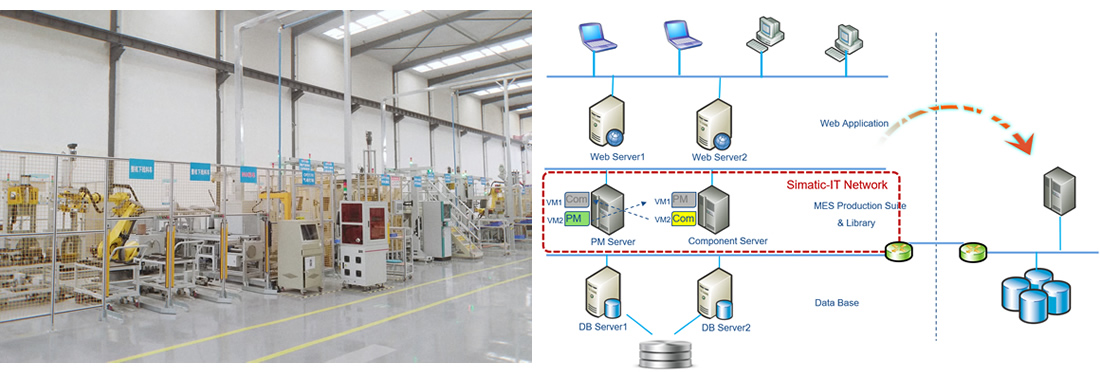

Manufacturing execution system (MES)

Depending on collecting and monitoring data and parameters during the process of new energy assembly line, MES aims at new energy electric-motor assembly line, providing reliable and accurate first-hand information in regard to enterprise production management and later product quality tracing